According to the Reprap website, Reprappers at the University of Bath, UK, have succeeded in making a rapid prototyper reproduce itself for the first time.

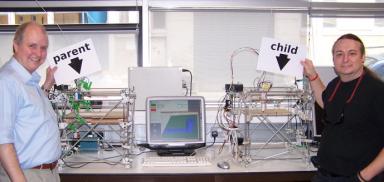

Adrian Bowyer (left) and Vik Olliver (right) with a parent RepRap machine, made on a conventional rapid prototyper, and the first complete working child RepRap machine, made by the RepRap on the left. The child machine made its first successful grandchild part at 14:00 hours UTC on 29 May 2008 at Bath University in the UK, a few minutes after it was assembled. image: http://reprap.org

The University of Bath's press release states:

"The materials, plus the minority of parts that the machine cannot print, cost about £300. All those non-printed parts can be bought at hardware shops or from online stores."

So if we're going to be picky, no it hasn't actually replicated itself in entirety - what has been achieved is that the Reprap design is now sophisticated enough to reproduce all its plastic parts, which were initially produced for the parent model by a conventional 3D printer. I like that the test of success is for the child Reprap to make the first component of its offspring Reprap - A highly accelerated world, this where generations are separated by just minutes! The successful reproduction was achieved by Adrian Bowyer and Vik Olliver, who also founded the Reprap project just 3 years and 2 months ago! Again, not bad as evolution goes, and I'm sure Reprap's current namesake would be proud!

Now its time to make your own. Good synopsis of the project, as ever, at Wikipedia.

The parent and child Repraps will be on display from the 4th June (today) to the 8th June at the Cheltenham Science Festival, if you're down that way.

Via Neel

UPDATE: Thanks to =ml= for pointing out Reprap's own showroom on Ponoko where one can have parts for the Darwin Reprap cut and delivered by Ponoko.

No comments:

Post a Comment